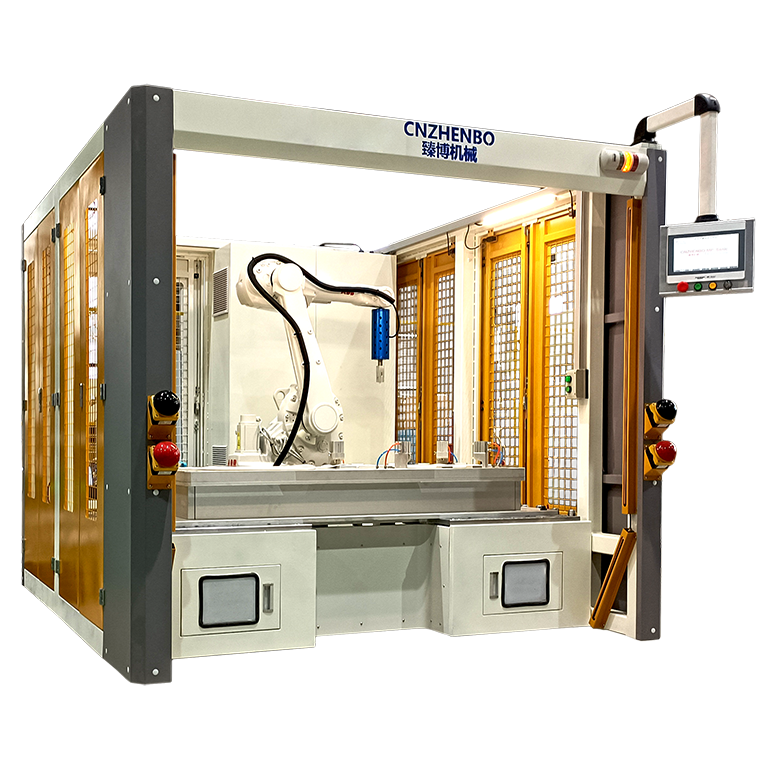

Robot application is the most method realizing automation of production and reduce human labor in production in maximum because of its flexibly programmable motion. MP Sonic designs proposal solution for customer specially according to custom requirement, applying multi-axis robotic system combining kinds of process technology, such as ultrasonic, laser, heating, milling, etc, to realize different working procedure and function in production line.

The Most Application:

1. Ultrasonic process, including ultrasonic spot welding, ultrasonic staking, ultrasonic cutting, ultrasonic trimming, ultrasonic scoring, etc

2. Spindle milling process, including spindle trimming, scoring/weakening for safety airbag tear line;

3. Laser process: laser welding or cutting on plastic material;

4. Handling operation, means shift parts between different location instead of human operator.

MP Sonic robotic process station mostly is applied in automotive interior & exterior production, such as dashboard (IP, instrument panel) assembly, door trim assembly, chair assembly, bumper assembly, headliner, etc.

6-Axis Ultrasonic Welding

6-Axis Ultrasonic Punching

6-Axis Ultrasonic Scoring Weakening

6-Aix Milling Weakening

6-Axis-Milling-Trimming

6-Axis-Ultrasonic-Trimming

Benefit:

Economical production cost: automation production, minimizes the human labor invested in production;

High efficiency in production: robotic process station can be operated in 24hours per day, maximizes the production capacity;

Quality ensured: with programmable system, the production line is operated in standardization, minimizing the impaction by human action to ensure qualification ration;

Optimized management:

Low investment cost for the updating of product: Programmable operation, can be put into production of different products with low extra capital investment through tooling changing over and trajectory programming.

Why choose MP Sonic to build Robotic Working Station?

1. Professional technical team: MP Sonic has set up strong team whose members are professional in process engineering, mechanical design, tooling design, programming, electronical design, robot programming and operation, machine trial and operation, etc, which provide you expert solution and technical support;

2. Projects experience: Because of so many years of experience not only in welding & cutting applied assembly technique, but also in robot application, especially applied in automotive industry, home appliance industry and bathroom equipment industry, etc, MP Sonic can design the most suitable proposal for customer, avoiding risk in maximum economical investment in both capital and time.

3. Abundant source supported: MP Sonic huge accumulation of source of material, element, academic & technology, etc, can be applied for customer’s application in efficiency, help customer in high utomation production and save human labors in maximum.

Milling Weakening Station

Machine weakens automotive dashboardmaterial to gain the invisible tear line of safetyairbag by millingScoring with high spindle. Machine applies high …

VIEW MORE

Robotic Ultrasonic Weakening Station for Automotive IP

MP Sonic designed ultrasonic weakening station is applied for the weakening the soft interiol material of automotive for the safety bag, such as the so…

VIEW MORE- 1