Servo Heat Stacking Machine

- Category:Heat Stacking Machine

- Phone:+86-15918523336

- Fax:+86-577-61517750

- Skype:

- E-mail:info@mp-sonic.com

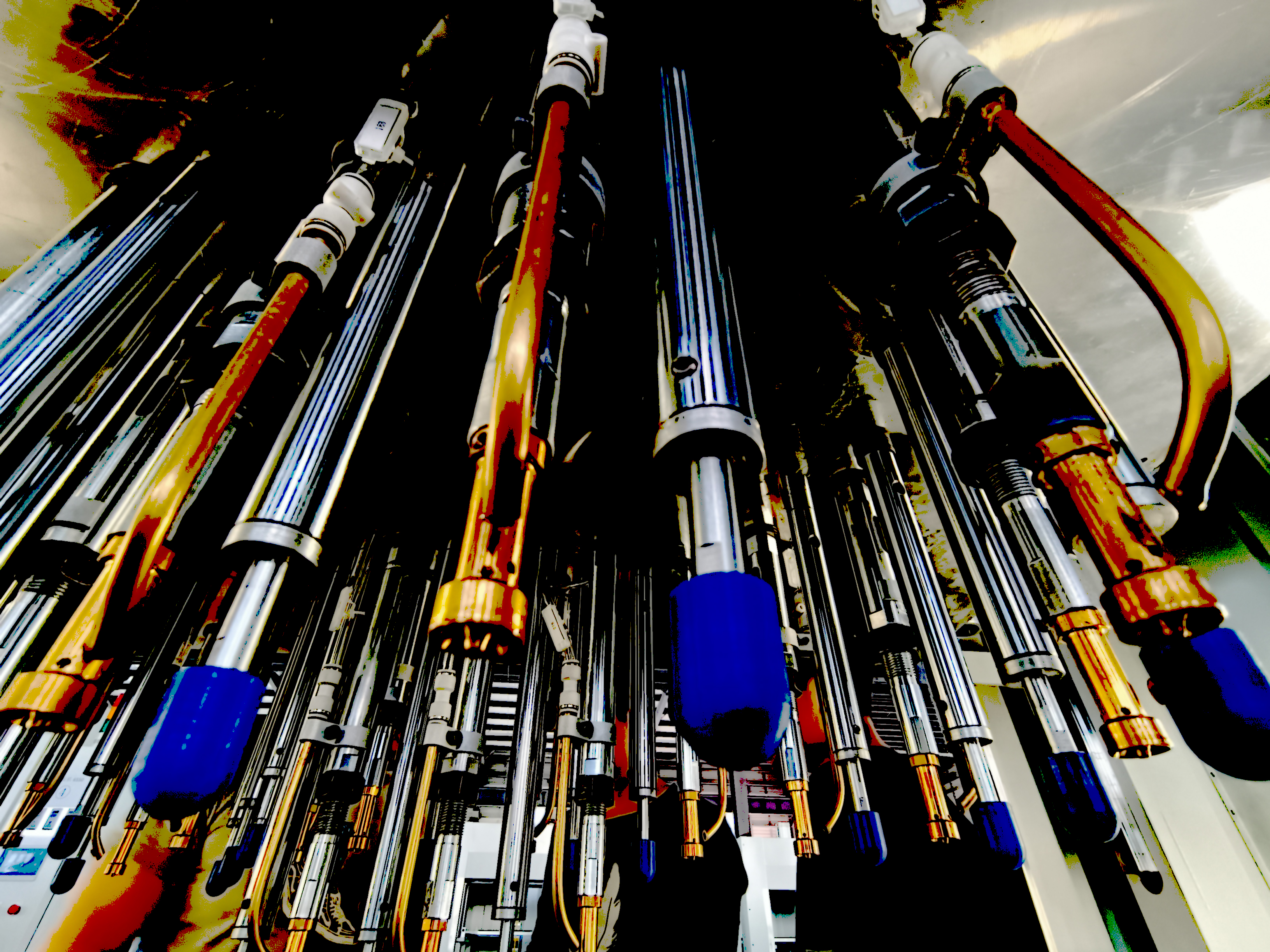

MP Sonic designed servo heat stacking machine applied servo motor system to control the stacking action and force pressure during operation. It is mostly applied for the riveting assembly of parts in big size, especially such as automotive door trim production.

This machine is half standardized machine designed, extra features & function should be designed basing parts design and actual requirement.

I. General Features:

1. Machine is standard design MSS-128090S Series. Machine frame and operation table is common application designed;

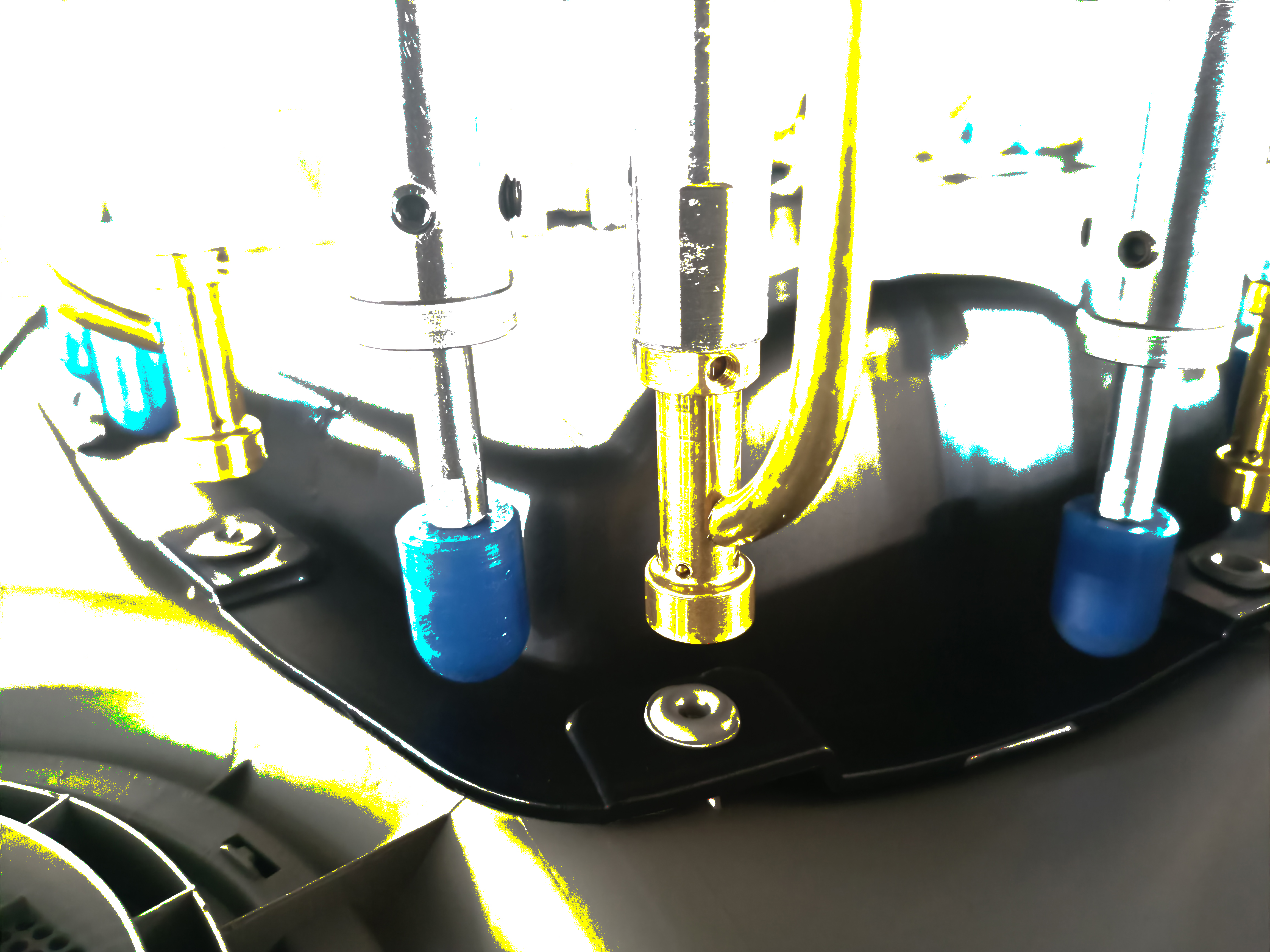

2. Machine control action action by Servo motor, action is fast in high precision control, stacking process is step controlled;

3. The vertical moving is guided by four gear bars for stability in precision;

3. Machine action controls sequence by PLC;

4. Machine set by HMI;

5. Each stacking tip temperature is independently PID controlled by PLC temperature module. Temperature is set on HMI;

6. Heater error ID is detected and indicated on HMI for easy fault-shooting;

7. Welding parameters storage is available to manage stacking process;

8. Alarm message/fault history is recorded for hot plate welding quality management;

9. Optical fence at front and safety door at sides and rear is designed for security;

10. Air blower is designed for cooling stacking points;

11. I-Could remote service system (WiFi type) for easy and quick service.

II. Specification:

1. Model: MSS-128090S Series

2. Power Source: 380V, AC, 3P, 50/60Hz;

3. Air Source: 0.6MPa;

4. Machine Dimension: 2300*1300*2340 (mm);

5. Space for tooling: L1280*W900*H550 (mm);

6. Power Consumption: 10KW;

7. Control Voltage: 24V;

8. Temperature Range: room temperature to 300℃.